Focusing on the main mining industry, the mining supply chain and technical service platform covering four types of businesses: technology, procurement, logistics, and trade provide technical and material supply guarantees for a number of super-large projects to be completed and put into production.

Mining Material Supply Service

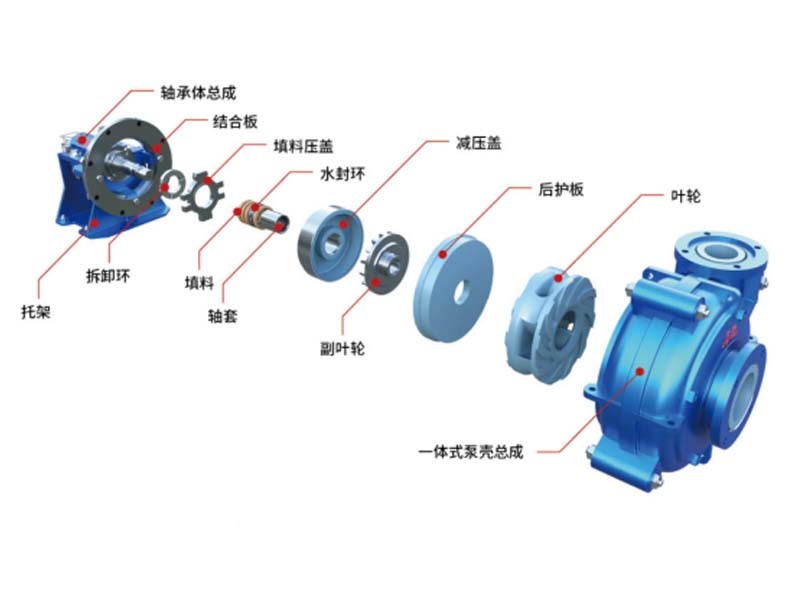

Ceramic slurry pump

- Commodity name: Ceramic slurry pump

- Product Description

-

Product overview

TZJD series ceramic slurry pump is a horizontal, axial suction, single-stage, single-suction, centrifugal slurry pump. The slurry weight concentration Cw of the solid-liquid mixture allowed to be transported is: 45% of ash (slag) slurry and coal slurry; Slurry and heavy medium 60%. This series of pumps combines the advantages of similar products at home and abroad and innovates in terms of hydraulic design, structural design and flow component materials. It has the characteristics of energy saving, low vibration, low noise, reliable operation, long service life, and convenient maintenance. Used in mines to discharge fluids containing mud and sand.

Material: high chromium alloy wear-resistant material

Scope of application:

Caliber: 80mm-600

Flow range: 65-3190m ³/h

Head range: 18.7-51.4m

Product advantages

The wear-resistant ceramic material is selected for the overcurrent parts, and the wear resistance is more than 3 times that of the high chromium wear-resistant alloy, and the hardness is as high as the Mohs hardness 9, second only to the diamond.

The new integrated pump casing design has simple structure and greatly reduces the length of dimensional inspection.

The shaft seal can adopt the company's patented technology of "self-circulating cooling combined mechanical seal" according to the working conditions, without packing, to achieve zero maintenance and ensure the effect of no leakage. The traditional auxiliary impeller packing seal shaft seal method can also be used.

Ceramic flow parts have high hardness, anti-cavitation and prolong service life.

The wear of ceramic flow-through parts is slow, which reduces the fluid loss of the pump and saves energy and reduces consumption.

The performance parameter table is as follows

Model Speedn(r/min) FlowQ(m³/h) Headm Efficiency% Shaft powerN(kw) Required NPSH m Model of supporting motor Power kW Host weightkg TZJD-80-370 1480 98 53.8 58.1 23.7 3 Y225M-4 45 730 145 52.5 68.9 27.9 190 50.7 70.8 32.7 980 65 22.6 58.1 6.9 2 Y180L-6 15 96 21.36 68.9 8.1 126 19.3 70.8 9.5 TZJD-80-400 1480 124 64 60.C 36 3.5 Y280S-4 75 730 162 61 65 41.4 248 53.8 67.8 53.6 980 82 28.1 60 10.5 2.5 Y200L2-6 22 107 26.7 65 12 164 23.6 67.8 15.5 TZJD-80-430 1480 130 73.5 60 41.7 3.5 Y280S-4 75 810 170 72.7 65 47.9 230 70.8 67.8 61.9 980 86 31 60 12.1 2.5 Y200L2-6 22 83 29.5 65 14 172 26 67.8 18 TZJE-80-470. 1480 166 86 57.8 67.3 4 Y315M-4 132 1100 276 80.1 68.9 87.4 331 76.3 71.3 96.5 980 110 37.7 57.8 19.5 2.5 Y250M-6 37 83 35.1 68.9 25.4 219 33.5 71.3 28 730 82 20.9 57.8 8.1 1.9 Y200L-8 15 136 19.5 68.9 10.5 163 18.6 71.3 11.6 TZJE-80-500. 1485 175 97.6 57.8 80.5 4 Y315M-4 132 1180 291 90.9 68.9 104.6 353 86.7 71.3 117 980 117 42.7 57.6 23.6 2.5 Y280S-6 45 195 39.9 68.9 30.8 233 38 71.3 33.8 730 87 23.8 57.8 9.8 1.9 Y225S-8 18.5 145 22.1 68.9 12.7 174 21.1 71.3 14

Key words: